Products

BILLETS & INGOTS

Stainless steel ingots are the initial, large-scale forms of cast stainless steel, designed for remelting or further processing. They serve as the foundational raw material for various downstream products. Billets, on the other hand, are semi-finished steel products with a smaller cross-sectional area, derived from ingots. They are commonly used as input for rolling, forging, and extrusion processes, leading to the creation of bars, rods, and tubes.

Both ingots and billets are fundamental in the stainless steel production chain, each playing a distinct role in shaping the final product.

RCS (Round Cornered Squares)

SS RCS, or Stainless Steel Round Cornered Squares, are semi-finished products characterized by their square cross-section with rounded corners. This design feature provides enhanced handling and processing capabilities compared to sharp-edged squares. SS RCS are utilized in various industrial applications, serving as a precursor to further shaping processes like rolling or forging.

Their consistent dimensions and improved handling characteristics make them a valuable material in manufacturing.

BRIGHT BAR

SS bright bars are stainless steel bars that have undergone a specialized finishing process to achieve a smooth, polished surface. This process, often involving cold drawing or grinding, enhances the bar’s dimensional accuracy and surface finish. Bright bars are prized for their aesthetic appeal and precise tolerances, making them suitable for applications requiring high-quality surface finishes and tight dimensional control.

They are commonly used in machinery components, precision instruments, and decorative applications.

ROUND BAR

SS round bars are cylindrical stainless steel products available in a wide range of diameters and lengths. They are versatile materials used across numerous industries due to their corrosion resistance, strength, and durability. SS round bars are employed in structural applications, manufacturing components, and various engineering projects.

Their availability in various grades and sizes makes them a widely adaptable material for diverse needs.

HEXAGONAL BAR

Stainless steel hexagonal bars are characterized by their six-sided cross-section, offering excellent torsional strength and ease of machining. They are widely used in applications requiring high torque transmission, such as fasteners, shafts, and valve components. The corrosion resistance of stainless steel ensures longevity in harsh environments, making these bars suitable for chemical, marine, and food processing industries.

Available in various grades and sizes, they cater to diverse engineering and manufacturing needs.

SQUARE BAR

Stainless steel square bars provide structural integrity and aesthetic appeal, making them versatile for architectural and industrial applications. Their uniform square shape allows for precise fabrication and assembly in frameworks, supports, and decorative elements. The high strength-to-weight ratio of stainless steel ensures durability and resistance to deformation under load.

These bars are essential in construction, machinery, and general fabrication, where reliability and visual appeal are crucial.

FLATS, PATTI (STRIP)

Stainless steel flats, also known as patti, are flat, rectangular bars used in a wide range of fabrication and construction projects. Their uniform thickness and width allow for easy cutting, bending, and welding, making them ideal for brackets, supports, and structural components. The corrosion resistance of stainless steel ensures these flats maintain their integrity in challenging environments.

Available in various sizes and finishes, they offer both functional and aesthetic versatility.

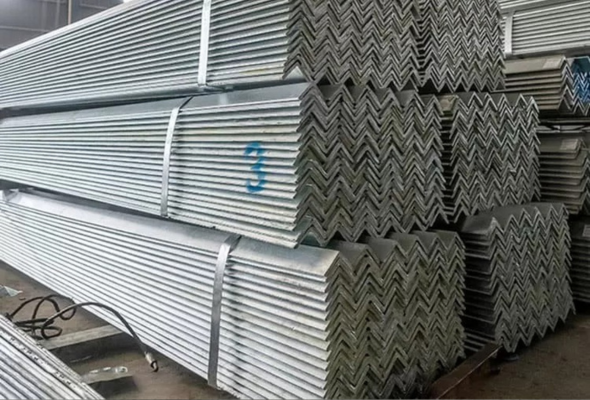

ANGLES

Stainless steel angles, with their L-shaped cross-section, provide structural support and reinforcement in various construction and fabrication applications. Their right-angle design allows for easy connection and assembly in frameworks, corners, and joints. The corrosion resistance of stainless steel ensures these angles maintain their strength and appearance in harsh environments.

They are essential in building construction, machinery, and general fabrication, where structural integrity and durability are paramount.

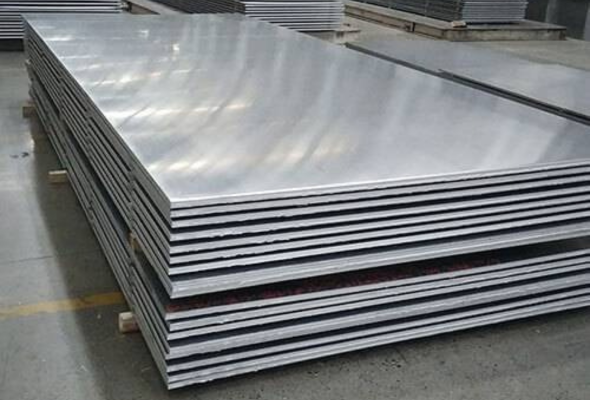

SHEETS

Stainless steel sheets are thin, flat products used in a multitude of applications, from architectural cladding to industrial equipment. Their smooth surface and corrosion resistance make them ideal for aesthetic and hygienic applications. Available in various thicknesses, finishes, and grades, they offer versatility for fabrication, forming, and welding.

These sheets are essential in industries like food processing, pharmaceuticals, and construction.

COILS

Stainless steel coils are long, continuous strips of stainless steel that are wound into rolls for efficient storage and transportation. They are used as raw material for various manufacturing processes, including stamping, forming, and welding. The continuous nature of coils allows for high-volume production and minimizes material waste.

Available in various thicknesses, widths, and grades, they cater to diverse industrial needs.

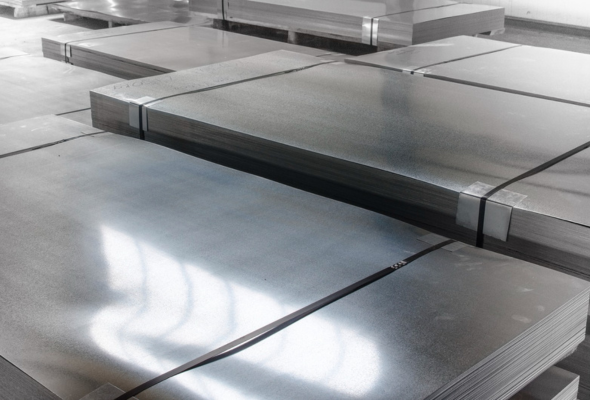

PLATES

Stainless steel plates are thick, flat products used in heavy-duty applications requiring high strength and corrosion resistance. They are essential in shipbuilding, pressure vessels, and structural components. The robust nature of stainless steel plates ensures they can withstand harsh environments and heavy loads.

Available in various thicknesses and grades, they cater to diverse engineering and construction needs.

SEAMLESS PIPES

Stainless steel seamless pipes are manufactured without any welding seams, providing superior strength and corrosion resistance. They are used in high-pressure and high-temperature applications, such as chemical processing, oil and gas, and power generation. The absence of welds eliminates potential weak points, ensuring reliability and longevity.

Available in various sizes and grades, they cater to diverse industrial needs.

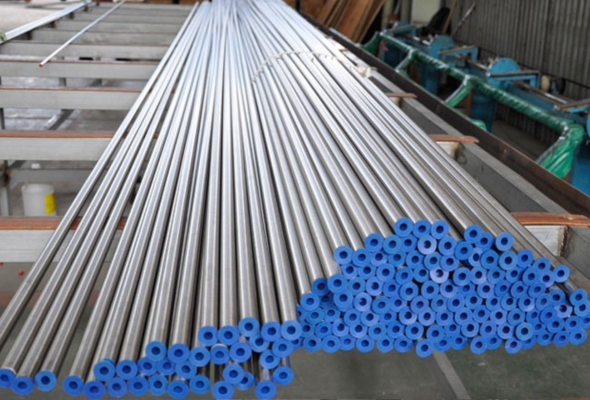

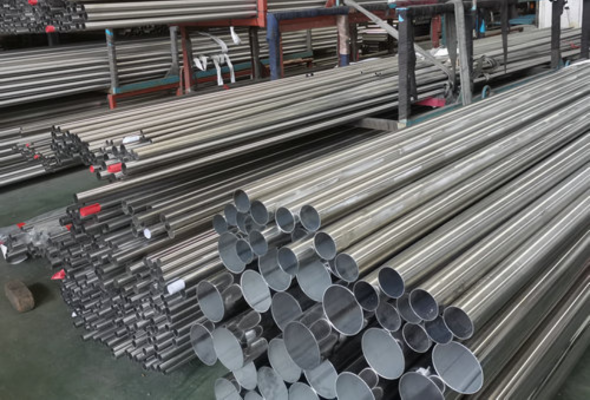

SEAMLESS TUBES

Stainless steel seamless tubes are similar to seamless pipes but typically have thinner walls and smaller diameters, used for more precise applications. They are essential in instrumentation, medical devices, and aerospace, where precision and reliability are crucial. The seamless construction ensures high-pressure containment and leak resistance.

Available in various sizes and grades, they cater to diverse engineering and manufacturing needs.

WELDED PIPES

Stainless steel welded pipes are manufactured by welding stainless steel sheets or strips into a tubular shape. While they have a weld seam, advancements in welding technology have improved their strength and corrosion resistance. They are used in various applications, including water and gas transportation, construction, and general industrial piping.

They are often a more cost-effective alternative to seamless pipes.

WIRED RODS

Stainless steel wire rods are long, coiled rods used as raw material for wire drawing, fasteners, and springs. Their flexibility and strength make them versatile for various manufacturing processes. The corrosion resistance of stainless steel ensures the final products maintain their integrity in challenging environments.

Available in various diameters and grades, they cater to diverse industrial needs.

FLANGES & FITTINGS

Stainless steel flanges and fittings are used to connect pipes, valves, and other equipment in piping systems. They provide a secure and leak-proof connection, essential in various industrial applications. The corrosion resistance of stainless steel ensures these fittings maintain their integrity in harsh environments.